The quality of the fuel plays a crucial role in the performance and efficiency of engines. Diesel fuel, as time passes, can become contaminated by impurities such as water and sediment. This can cause engine failure and costly repairs. The process of polishing fuel is a way to prevent fuel contamination and maintain the smooth operation of engines.

Polishing of fuel is also known as polishing the diesel fuel. It involves the removal of impurities, contaminants and pollutants from diesel fuel. Polishing fuel is a service that is performed by experts using the latest tools and techniques to restore fuel to its original state. Fuel polishing improves engine performance reduces maintenance costs, and prolongs the lifespan of equipment by removing harmful substances and improving the quality of fuel.

There are numerous fuel polishing companies that can meet the needs of different industries which use diesel fuel. These services employ highly skilled technicians who possess expertise in fuel systems and comprehend the intricacies of fuel contamination. Their extensive knowledge and special equipment allow them to recognize issues related to fuel and employ the proper methods of polishing your fuel.

The process of polishing fuel has as its principal goal removal of water, sediments microorganisms, sludge and sludge from diesel fuel. Water can build up in fuel tanks as a result of leakage or condensation, leading to corrosion, fuel degrading as well as the growth of bacteria and fungi. Sediment, however, is a result of the presence of impurities or degraded components of the fuel. These contaminants may clog the injectors and filters as as other essential components. This could result in lower engine performance or even a complete breakdown.

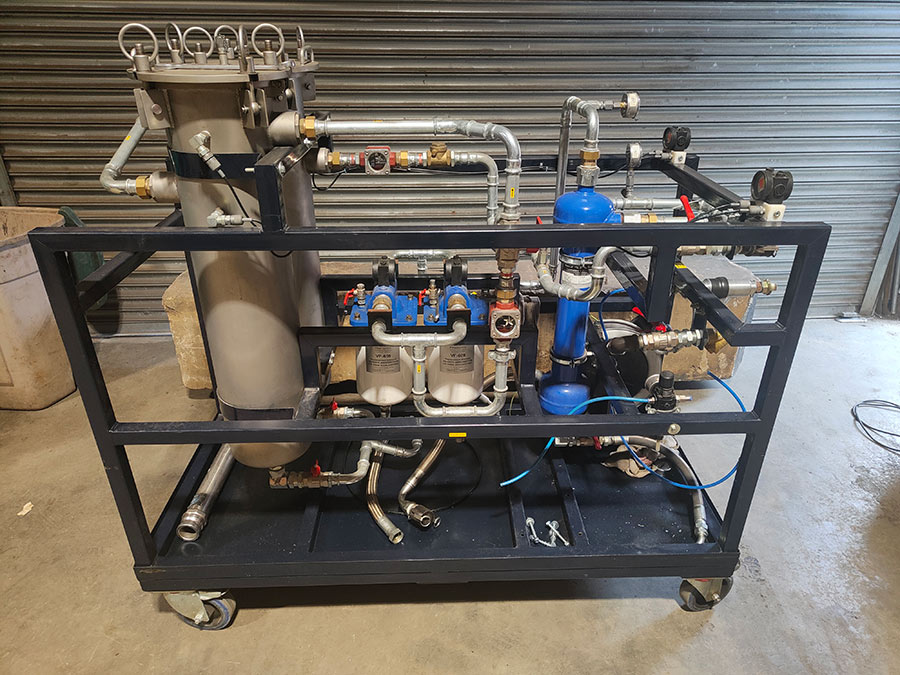

Fuel polishing typically involves a multi-step process. It begins with sampling of fuel and analysis to determine the level of contamination to determine the best procedure to take. Following the analysis, experts use filters to eliminate impurities and contaminants from the fuel. These systems use a variety of filters and media to efficiently capture and remove fuel-borne contaminants.

Regular fuel polishing offers several key benefits. In the first place, it improves the quality of fuel and ensures that engines receive clean and consistent fuel for optimal combustion. Additionally, it improves fuel efficiency and performance. This can result in reduced emission and cost savings. Additionally, it helps to reduce the possibility of engine failure and damage due to contamination of fuel. By removing harmful substances polishing helps to maintain the integrity of engine components that are crucial, extending their life and decreasing the frequency of repair and downtime.

Regular polishing of diesel fuel (also called diesel polishing) has many advantages for maintaining fuel quality. In the first place, it helps get rid of sediment, water, and microbial contaminants that affect the performance of engines. The quality of the fuel is improved significantly by removing these impurities using the polishing process for diesel. This is a result of improving combustion efficiency, resulting in improved fuel efficiency and less emissions. Regular polishing of the diesel engine also stops the fuel filter from becoming blocked injectors, fuel filters, and other crucial components. This decreases the risk of engine damage, or expensive repairs. Fuel polishing is also important to prolong the life of the fuel storage system by reducing the accumulation of sludge corrosion and other contaminants. Regular polishing of diesel engines or fuel cleaning can improve engine performance and decrease expenses. Also, it increases the reliability of equipment.

The services of fuel polishing are specifically designed to meet the needs of specific industries and their applications. It is a flexible option that can be employed to combat fuel contamination in diverse industries. From backup generators for marine vessels to construction equipment, transport fleets, and construction equipment, fuel-polishing provides a variety of solutions to combat fuel contamination. The process of polishing fuel is crucial in industries that require an uninterrupted and reliable power supply. It’s also vital for those who work in remote areas or harsh environments where the quality of the fuel could be compromised.

In summary, polishing the fuel is a crucial procedure to ensure the quality and purity of diesel fuel. It enhances the performance of engines decreases maintenance costs and prolongs the life of the equipment by removing impurities and contaminants. Professional fuel polishing enables companies to ensure their operation, boost performance, and decrease the risks associated fuel contamination. The process of polishing fuel is a potent tool that is able to boost the performance of diesel fuel.